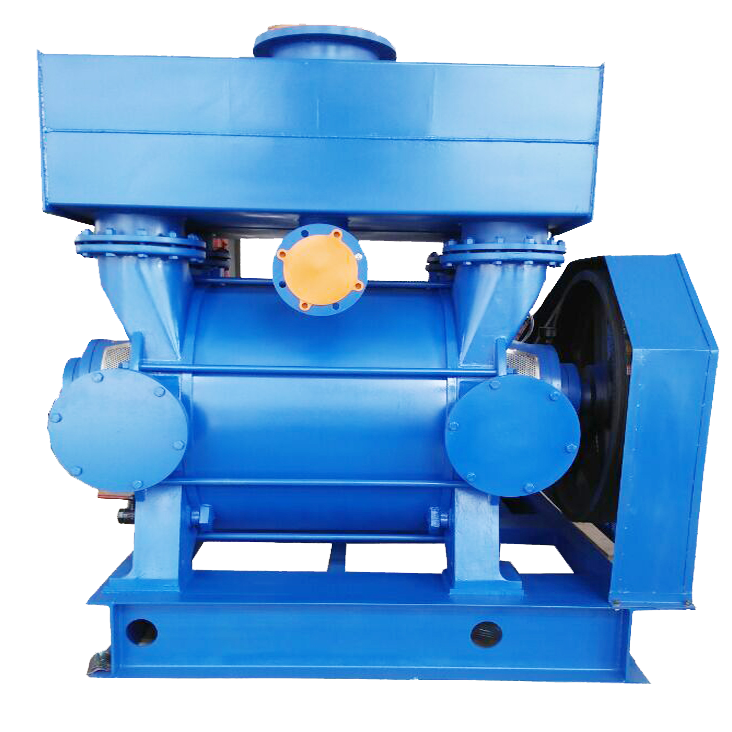

EVP 2BE3 Series

Liquid Ring Vacuum Pump

2BE3 Series Liquid Ring Vacuum Pumps Are Usually Used

Liquid Ring Vacuum Pump

2BE3 Series Liquid Ring Vacuum Pumps Are Usually Used

To Suction The Gas Without Solid Particle, Undissolved And

Noncorrosive Gas To Generate Vacuum And Pressure In The

Closed Container. By Changing The Pump Material, They

Can Also Be Used To Suction Corrosive Gas Or Use Corrosive

Liquid As Operating Liquid. They Are Widely Used In

Paper-Making, Chemical, Petrification, Light Industry, Pharmacy,

Instruments, Metallurgy, Construction, Electronical Appliance,

Coal-Cleaning, Mineral Concentration, Fertilizer, Etc.

2BE3 Liquid Ring Vacuum Pump Is Single Stage Pump With Simple Structure. It’s Easy Maintenance, Reliable,Efficient And Energy-Saving Operation . They Can Run Under Tough Working Conditions With Large Drainage Discharge And Changing Load Impact. 2BE3 Vacuum Pumps Adopt Unique Polytetrafluoroethylene Valve Plates (Former Liquid Ring Pumps Use Ball Valves) For Their Exhausting Systems. Each Valve Plate Is Covered On Vents In Outer Side Of A Port Plate And Fixed By A Stainless Steel Baffle At Its Other Side. Curvature Of The Valve Plate Changes With Inlet Pressure So That Pumping Medium Can Be Discharged When It Reaches The Inlet Pressure. Such Structure Avoids Over-Compression In A Vacuum System And Automatically Adjusts Exhausting Area To Lower Power Consumption, Thus A Best Operating Efficiency Can Be Obtained.

The Key Parts Of 2BE3 Series Liquid Ring Vacuum Pumps, Such As Distribution Plate, Impeller And Pump Shaft Are Simplified In Structure With Performance Improved, Thus It’s Very Energy-Saving.

Dynamic Balance Problem Is Radically Solved Because During Impeller Welding, Blades Are Formed By One-Step Stamping With Rational Molded Lines And All Wheel Hubs Are Processed. The Impeller And Pump Shaft Combined By Shrinkage Interference Fit Perform Reliably And Smoothly. Blades Of The Impeller Will Obtain Good Ductility After The Impeller Is Welded And Processed By Overall Heat Treatment, Thus Impact Resistance And Flexure Resistance Of The Blades Are Fundamentally Guaranteed The Application Under Tough Working Condition With Changing Load Impact. The 2BE3 Pumps Are Equiped With Gas-Water Separators Itself, Many Position Has The Exhausting Hole. It Is Very Easy To Connect With The Vacuum System. What’s More, The Pump Cover With Inspeciton Window Which Can Regulate The Gland Packing Of The Shaft To Adjust The Impeller And Distributoring Plate. All Vacuum Pumps Will Be Subjected To Strict Inspections And Tests In Our Testing Center So As To Guarantee Their Excellent, Reliable And Long Lasting Performances.